Due to its modern conception, this flow measurer embodies the most advantageous and revolutionary system for instantaneous dosing over product flow.

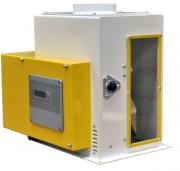

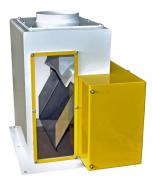

The RFP Ponderal Flow Controller consists of a metal box where the product flows, one shutter and one survey unit that is composed of a weighing disk and an electronic device for controlling and programming of the measurer.

The opening of the valve, controlled by an electronic servomotor, allows the outflow of the free flowing product on the weighing disk; this happens through a stress decomposition system (vertical resultant opportunely corrected by the electronic device) and compared with the preselected flow of the selected course, it determines the actual product flow and therefore the instantaneous output/h.

In normal conditions, the shutter never reaches the maximum opening: if that happened it means that, the product quantity is not enough to guarantee the production. In this case, an alarm will be activated. In case of lack of power the valve shuts automatically, hindering the product flow.

The servomotor, equipped with a universal clamp, can be mounted rapidly and directly on the shaft of the valve and fixed through an anti-torsion bar. The valve can be hand operated and stopped at any position. Its unblocking is held manually or automatically applying the tension of feeding.

Technical characteristics:

- Weighing block with loading cell;

- Weighing control with servomotor system;

- Used in the grain silos cells discharge in order to obtain mixes drawing different percentages from the cells.

The following functions are available:

- Preselection of dosing percentage;

- Preselection of quantity to dose;

- Incorporated general totalizator with 5 digits with floating point;

- Viewer on 5 course display in percentage or Ton/H, general totalizer, partial totalizer;

- Serial line RS 422/485 with PC remote control, by Master or panel viewer;

- External consensus Start/Stop contemporary of more dosers or flooding probe;

- Zero self-regulation system at each dosing start;

- Feasibility to apply eventual correction through keyboard;

- Dosing signalling exit per finished quantity ;

- Signal exit 4-20 mA for the output/h;

- Feeding 24 Vac.