Product - Mills

Versatility and Productivity

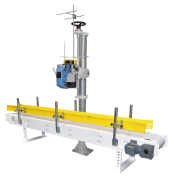

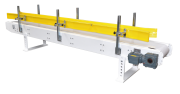

Sangati Berga crown precision and high productivity for their open-mouthed bagging systems with the speed and reliability of the LCS Sewing Line. Comprised essentially of a conveyor belt which receives open-mouthed bags and carries out the closing and sewing process, whereas, in addition to the high performance automated sewing head and its support column, the LCS Sewing Line can also be provided with various accessories and functions, such as:

• Double headed sewing column: This version allows for exchange between the twin sewing heads whenever necessary avoiding the need for production line stoppages for set-up, maintenance or cleaning;

• Motorised adjustment of head height and/or conveyor belt height: Allows for rapid line adjustment when bag height is changed. For example, when alternating between 25Kg and 50Kg bags;

• Automated bag feeder / folder: Automatically prepares and inserts the mouth of the bag onto the sewing head;

• Bag hopper: Positions bags horizontally and delivers bags to the transmission line.

The LCS Sewing Line can be used on conventional or laminated polypropylene bags made of multi-layered raffia or of paper of various sizes and is fully adjustable in order to provide the best performance for each application.

Conveyor belt velocity of 12m/min and precision adjustment of sewing speed permits a balance between high production capacity and high quality sewing which is free of errors, ruptures or leaks.