The ever growing demands on salubrity requested by our mill industry customers has fostered our research center experts to develop a especial machine towards the processing of wet grains before their rest period.

In the cleaning diagram, this machine is applied after the intensive moisturizing of the first and second bath and before being sent to the resting containers.

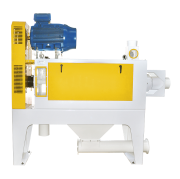

The wet grain goes through an abrasion process against itself, against the beating paddles of the rotor and against the screen; this particular action allows extracting from the weat grain up to 3% of outer and waterproof cuticle.

The abrasion intensity is attained by acting on brake discs placed at the machine outlet.

The scourer screen is constantly kept clean through high pressure air insufflation by the rotor shaft.

An optional thermal battery reduces the discharge product moisture if necessary.

Advantages:

- Wheat grain perfect cleaning;

- Bacteria presence maximum reduction;

- Rest time reduction of about 80% if integrated to our regular cleaning but with humidifying screw BI-MIX and 95% if introduced into our innovative “vacuum-pressure” system;

- Use feasibility like a coupled machine such as intensive humidifier or like a separate machine.